Greetings, construction enthusiasts! Today, we’re delving into a construction technique that could reshape the way you approach wall assemblies – the double-studded 2×4 wall. Whether you’re a DIY enthusiast or a seasoned builder, this cost-effective and high-performance solution might just be the game-changer you’ve been looking for.

The Double-Studded 2×4 Wall

Cost-Effective Construction

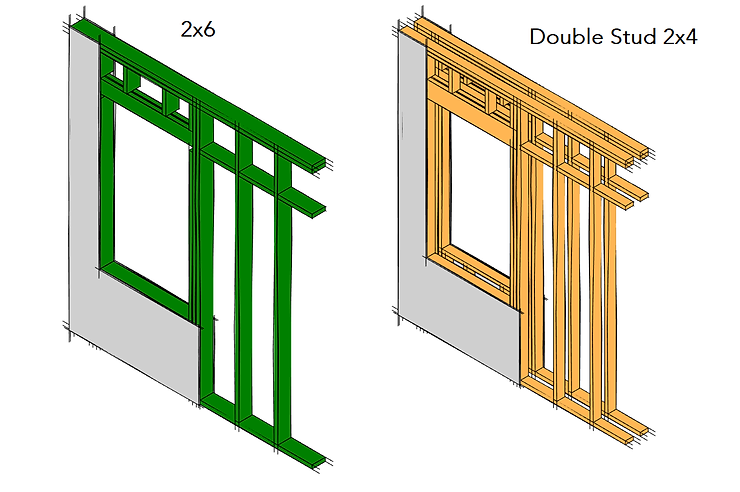

When it comes to wall assemblies, the choices are vast, but the double-studded 2×4 wall stands out for its innovative design. This assembly involves two separate 2×4 walls, with the inner wall strategically avoiding contact with the outer wall. The key feature here is the 3-inch gap between them, creating a total cavity depth from stud to stud of 10 inches.

The beauty of this design lies in its cost-effectiveness. Despite using 2×4 studs instead of the more common 2×6 studs, the doubled-up walls mean you’re still using twice as many studs. Surprisingly, a 2×4 stud is roughly 60% of the cost of a 2×6 stud, resulting in twice as many studs at 60% of the cost, making lumber expenses comparable to a conventionally built structure.

Double-Stud Walls Gaining Ground in Cold Climates

Double-stud construction is making waves, especially in cold climates (zone 4 and above). It’s often employed to gain large amounts of insulation, using common building materials and avoiding environmentally harmful foam. The exterior is constructed with a typical 2×4 load-bearing wall, and then a second non-load-bearing wall is built to the interior, spaced away from the exterior wall.

Performance Matters

Finding the right balance between cost-effectiveness and performance is crucial in any construction project. The double-studded 2×4 wall excels in this regard. For optimal performance, a high-performance wall assembly should provide a good R-value and feature a complete thermal break.

Unlike traditional 2×6 walls where studs touch both the interior and exterior, our assembly introduces a complete thermal break between the two walls. This break significantly reduces heat transfer from the inside to the outside.

Tailoring Insulation to Your Needs

One of the remarkable features of the double-studded 2×4 wall is its adaptability. By adjusting the gap between the two walls, you can customize the insulation level to meet specific R-value requirements. Currently set at a 3-inch gap, you can easily increase or decrease it based on your insulation needs. For instance, moving to a 5-inch or 7-inch gap provides flexibility without reinventing the construction process.

For insulation, consider options like dense pack cellulose, involving a net to cover the entire wall and a pressurized hose to fill the cavity with dense pack cellulose. This method ensures every nook and cranny is efficiently filled, resulting in an impressive R-value for the wall.

Simple Framing, Powerful Results

What sets this wall assembly apart is its simplicity. There’s no need for complex construction methods; it’s just a matter of building two 2×4 walls with a 3-inch gap between them. Any skilled framer can easily execute this straightforward framing technique, making it an accessible option for various construction projects.

What’s Next?

As you explore new avenues in construction, consider the double-studded 2×4 wall for its cost-effectiveness and high-performance characteristics. Happy building!